Hydrothermal Synthesis of Metal–Organic Frameworks, Zeolites, and Related Materials: A Versatile Route to Crystalline Porous Solids

Introduction: Why Hydrothermal Synthesis Matters in Porous Material Design

Hydrothermal synthesis is a cornerstone technique in materials chemistry, enabling the formation of crystalline solids under elevated temperature and pressure in aqueous media. This method is particularly effective for producing metal–organic frameworks (MOFs), zeolites, and zeolitic imidazolate frameworks (ZIFs)—materials prized for their high surface area, tunable porosity, and chemical functionality.

Keywords: hydrothermal synthesis, metal–organic frameworks, zeolites, ZIF-8 synthesis, porous materials for catalysis

Fundamentals of Hydrothermal Synthesis

The process involves dissolving precursors in water or mixed solvents and heating the solution in a sealed autoclave at temperatures typically between 100–250 °C and autogenous pressures above 1 bar. This environment promotes nucleation and crystal growth, often yielding highly ordered frameworks with minimal defects.

Key Parameters Influencing Crystallization

Temperature and time: Higher temperatures accelerate nucleation but may reduce crystal size.

pH and mineralizers: Control solubility and framework topology.

Structure-directing agents (SDAs): Organic molecules that guide framework assembly.

Metal–ligand ratios: Crucial for MOF and ZIF formation.

Applications: From Catalysis to Gas Storage

Hydrothermally synthesized materials are used in:

Catalysis: Zeolites like SAPO-34 and ZSM-5 are industrial catalysts for cracking and methanol-to-olefin (MTO) reactions.

Gas separation and storage: MOFs such as HKUST-1 and UiO-66 exhibit high CO₂ uptake.

Sensors and drug delivery: ZIF-8 and MIL-series MOFs offer chemical selectivity and biocompatibility.

Case Studies and Research Highlights

Zeolites: A Springer chapter outlines how hydrothermal synthesis enables precise control over pore architecture in zeolites and mesoporous materials, enhancing catalytic performance.

MOFs: Yaghi et al. (1995) demonstrated the hydrothermal synthesis of Cu(4,4′-bpy)₁.₅(NO₃)(H₂O)₁.₂₅, a 3D MOF with extended channels and zeolitic properties, using a stepwise temperature ramping protocol.

ZIF-8: Lestari (2012) optimized the hydrothermal synthesis of ZIF-8 crystals with tunable size and morphology by adjusting the 2-methylimidazole/Zn²⁺ ratio and surfactant content.

Hybrid Systems: Yao et al. (2022) synthesized Zr-modified SAPO-34 zeolites using UiO-66 as a co-template, achieving hierarchical porosity and enhanced MTO catalytic lifetime.

Keywords: ZIF-8 hydrothermal synthesis, MOF crystal growth, zeolite catalysts

Design Considerations for Laboratory Synthesis

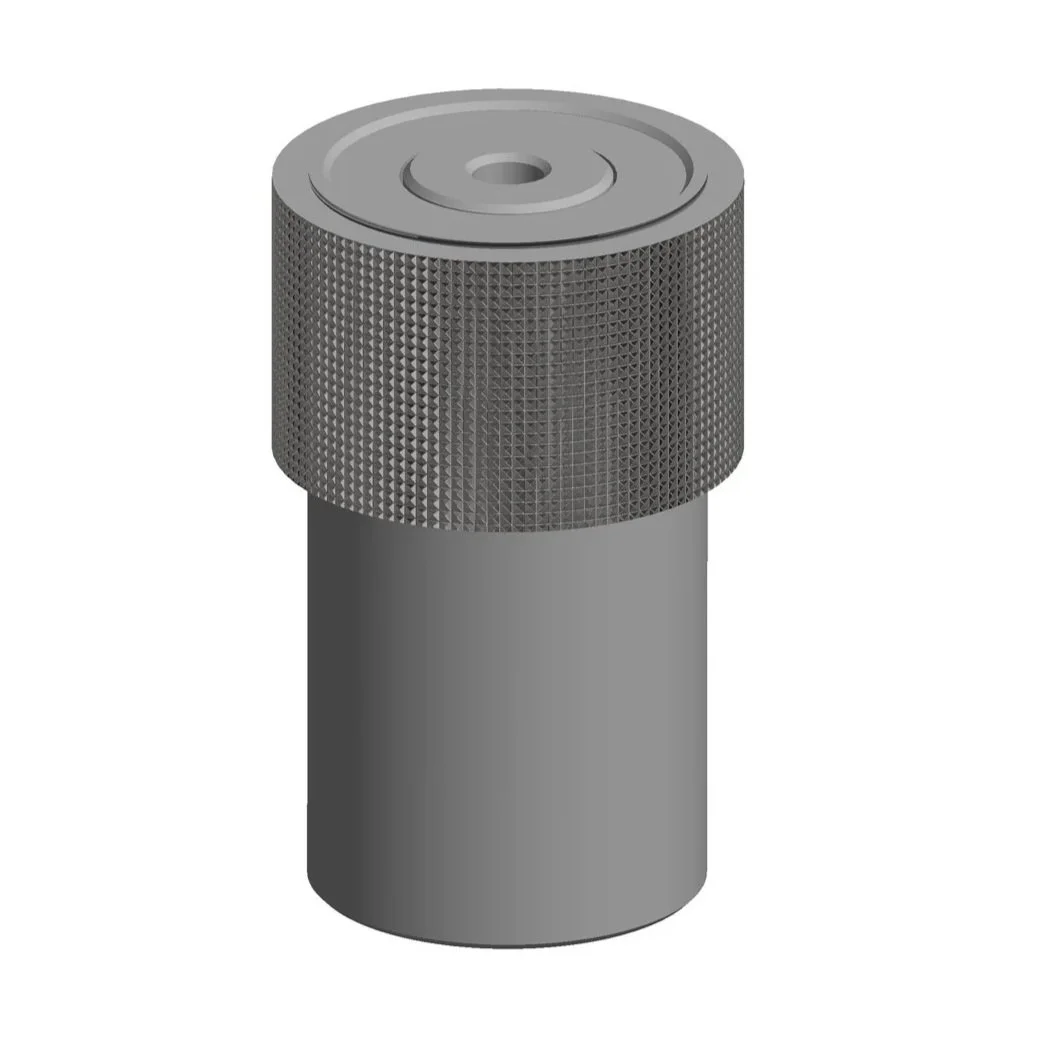

Reactor material: Teflon-lined stainless steel autoclaves resist corrosion and allow visual inspection of crystallization.

Heating profile: Stepwise temperature ramps can improve crystal quality.

Post-synthesis treatment: Washing, solvent exchange, and activation (e.g., vacuum drying) are critical for porosity development.

Safety and Scale-Up Challenges

While hydrothermal synthesis is scalable, it requires careful pressure management and thermal control. Autoclave integrity, venting systems, and adherence to pressure vessel standards (e.g., ASME BPVC) are essential for safe operation.

Conclusion: A Platform for Tailored Porous Materials

Hydrothermal synthesis remains a versatile and powerful method for producing crystalline porous materials with applications across catalysis, separation, and energy storage. Its adaptability to diverse chemistries and scalability make it indispensable in both academic and industrial settings.

Featured Product