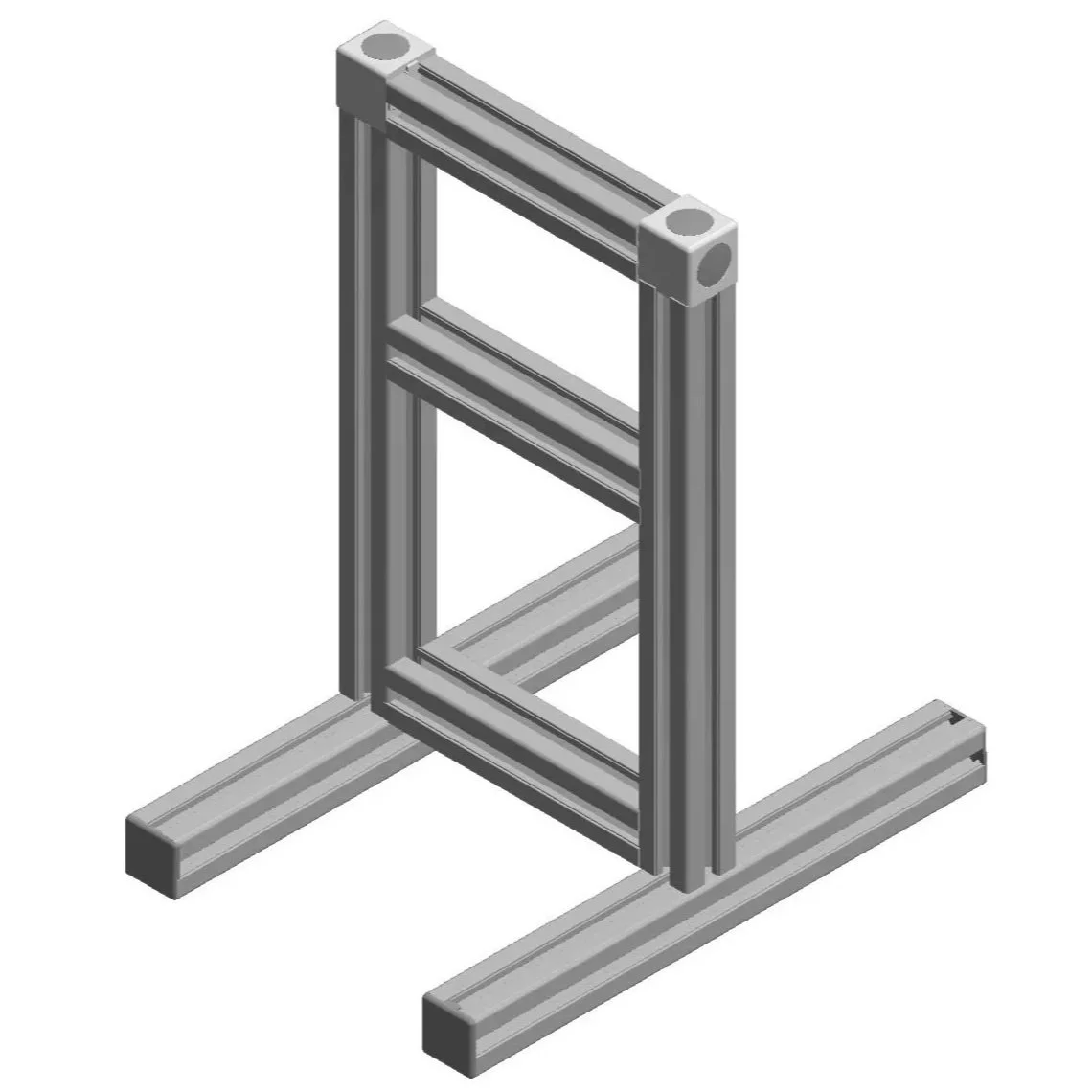

Customised Equipment and Instrumentation Frames

Forge Pressure Equipment is pleased to partner with you to design and deliver a custom frame to mount your instrumentation or equipment — tailored precisely to your needs, whether or not it relates to our pressure vessels.

Why choose a custom Forge frame?

Fit-for-purpose: frames designed to accommodate vessels, valving, mass flow controllers, transducers and electrical components — all arranged for accessibility and reliable operation.

No guesswork: we fabricate, machine and 3D print bespoke holders and fixtures so every component mounts accurately with secure, repeatable connections.

Cleaner installations: purpose-made mounting removes improvised brackets and sloppy connections that compromise performance, safety and serviceability.

How the process works

Contact us with your requirement and a brief description.

We request essential details — dimensions, mounting distances, load points and, if available, photos or sketches.

We provide a clear quotation. If you accept, we proceed to design.

Our engineers produce a CAD model of the frame and any bespoke fixtures or holders. You review and approve the design.

Once approved, we manufacture and assemble the parts using in-house fabrication, machining and 3D printing as required.

Delivery is arranged: the frame can be shipped fully assembled or partially disassembled for ease of transport. On-site installation and associated pipework services are available and can be quoted alongside the frame.

What you’ll get

A robust, professionally engineered frame matched to your components and workflow.

Custom fixtures that secure sensors and devices without stress or misalignment.

Reduced installation time and fewer field modifications.

Optional installation by our trained technicians to ensure correct integration with pipework and instrumentation.

We tailor materials and finishes to the environment and application, and we test fit-critical interfaces before delivery. If you’d like, we can include documentation and drawings for your records and future maintenance.

Tell us what you need — sizes, photos and any specific requirements — and we’ll provide a quote and a CAD-backed design workflow to get your customised mounting solution delivered and installed.