Equipment and Instrumentation strands

Is your equipment the wrong height, hard to move, or needing a secure home alongside other instruments? Our custom-built stands are the practical, durable solution — designed and manufactured to your exact requirements.

Why choose Forge Pressure Equipment custom stands?

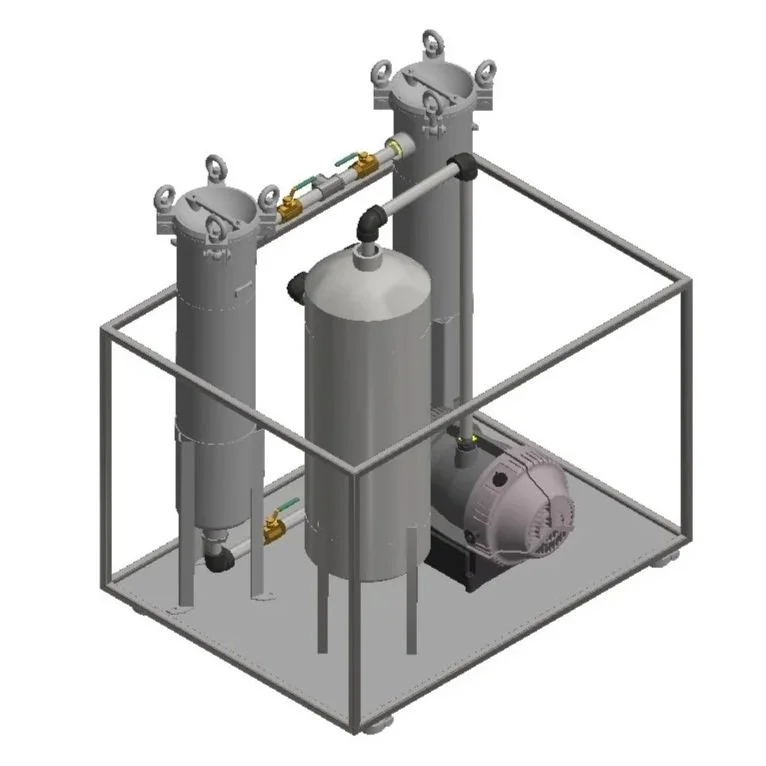

Purpose-built for fit: We consult with you to understand dimensions, weight distribution, connection points and any ancillary items the stand must accommodate. The result is a stand that integrates precisely with your equipment — no awkward gaps, no improvised supports.

Configurable mobility: Fixed stands, lockable castors, or heavy-duty wheels — specified to match floor type and usage. Mobility options include brakes, dampers and quick-release mechanisms so you can safely reposition kit when needed and lock it firmly in place during operation.

Load-rated and compliant: Every stand is engineered and rated for the loads and dynamic forces of your application. We design to applicable safety and test standards so you can rely on stability and regulatory compliance in lab and industrial environments.

Modular housing and integration: Combine instruments, controllers, power strips, trays, cable management and enclosures in a single compact footprint. Shelving, mounting plates and bespoke housings are integrated at design stage to keep your workflow efficient and tidy.

Materials and finishes to suit the environment: Stainless steel for corrosion resistance, powder-coated steel for durable finishes, or chemically resistant linings where required. Surface treatments are chosen to suit cleanliness, chemical exposure and aesthetic needs.

Practical ergonomics and serviceability: Height and reach are optimised for operator comfort and safety. Removable panels, accessible fastenings and service clearances ensure routine maintenance and inspections are straightforward.

Rapid prototyping and production: From CAD drawings and mock-ups to finished fabrication, we deliver clear design approvals and predictable lead times. Prototypes and trial fittings can be arranged so you can validate the design before final build.

Tested before delivery: Stands are functionally tested under load and inspected for weld quality, fastener torque and finish. We ship only when the stand meets our standards and yours.

Typical applications

Laboratory pressure vessels and associated instrumentation

Analytical instruments and controllers

Pumps, compressors and ancillary plant items

Modular test rigs and mobile service trolleys

How we work

Consultation: Site or virtual survey to capture dimensions and requirements.

Design: CAD model and specification shared for approval.

Build: Fabrication with chosen materials, finishes and mobility options.

Test & deliver: Load testing, inspection and delivery with installation support if required.

Get a stand that fits your equipment — not the other way around. Contact Forge Pressure Equipment for a consultation and quote tailored to your instruments, workflow and safety needs.