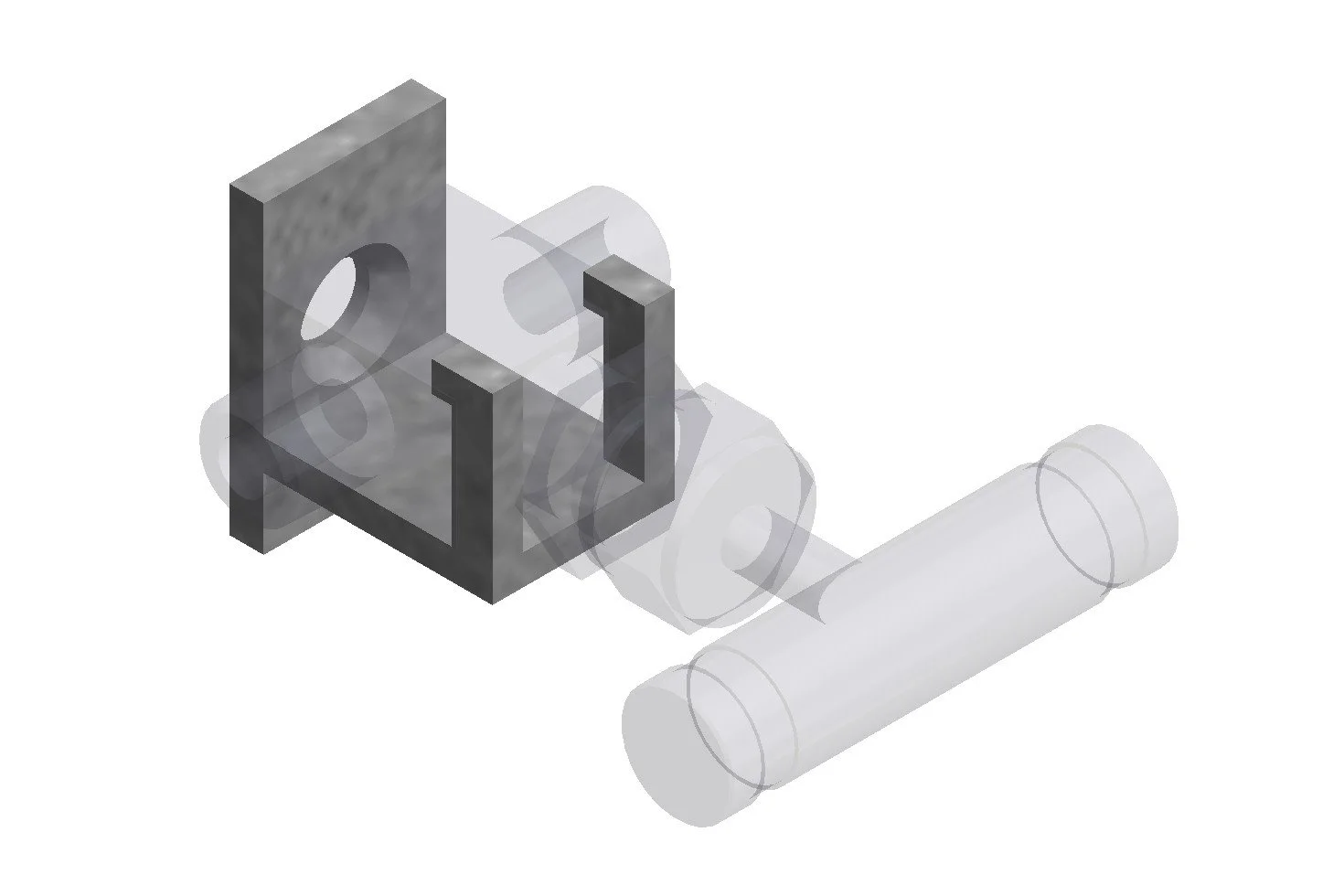

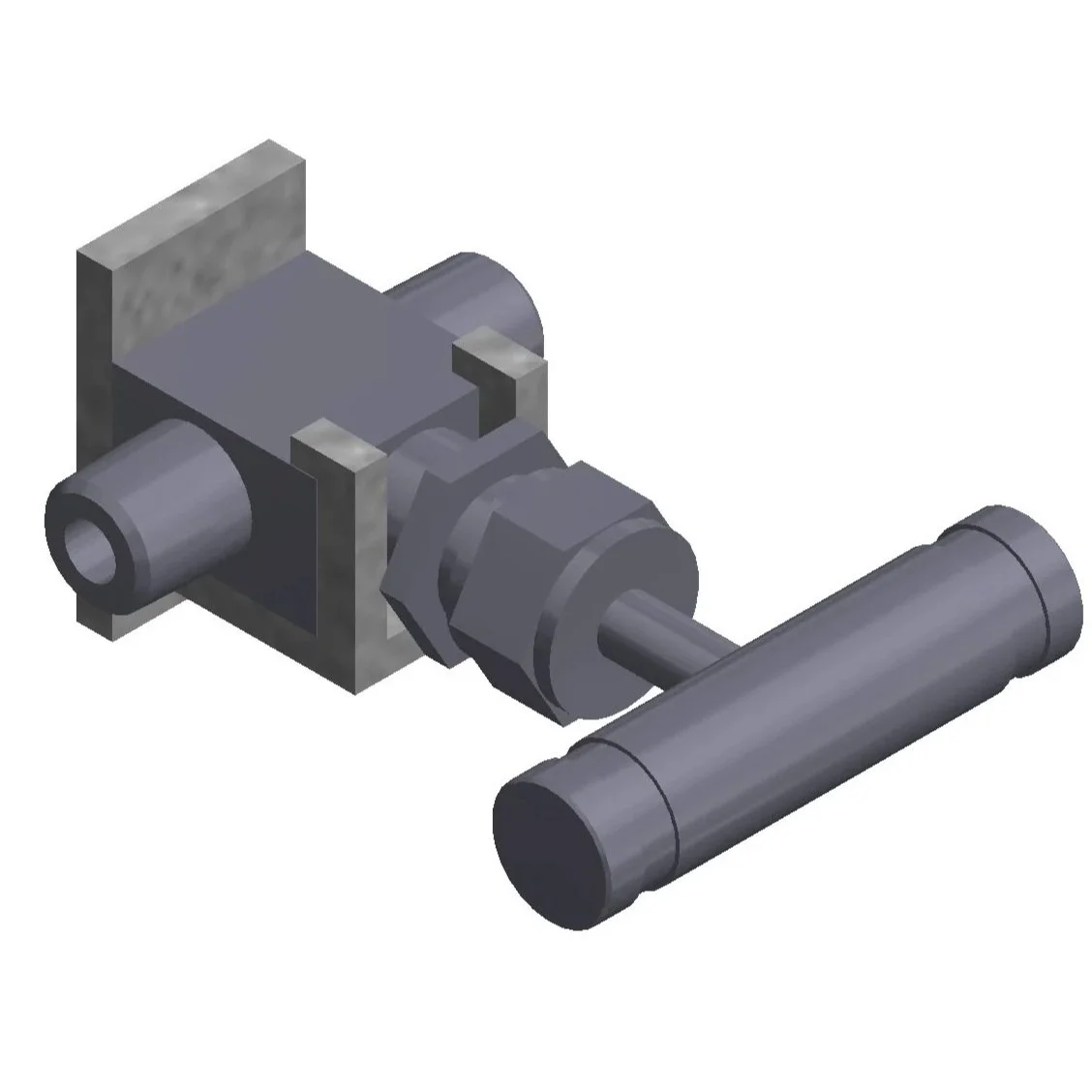

Custom Fixtures

Custom fixtures to secure valves, pipework, mass flow controllers, sensors, vessels and instrumentation — built to fit your process, tolerance and throughput.

Why choose Forge Pressure Equipment fixtures?

Tailored fit: Fixtures designed from your drawings, models or on-site measurements to locate and support each component precisely, reducing alignment errors, vibration and leaks.

Material and process flexibility: We deliver fabricated, CNC-machined or additive-manufactured (3D printed) fixtures depending on strength, chemical compatibility, thermal performance and lead time requirements.

Repeatable positioning: Locating features, datum faces and clamp points ensure instruments and pipework return to the same position after maintenance or removal, saving commissioning time and improving measurement repeatability.

Reduced installation risk: Custom brackets and supports relieve mechanical loads on valves, sensors and MFCs, protecting fittings and electronic connections and reducing downtime from stress fractures or misalignment.

Modular and serviceable: Fixtures can be designed as modular subassemblies for easy access, rapid replacement and future expansion without rework of surrounding systems.

Compliance and traceability: Manufactured to your specified materials and processes, with documentation and serialisation options to support quality systems and audits.

What we offer

Fabricated fixtures: Robust, cost-effective solutions for larger items and assemblies. Ideal for corrosive environments or where welded substructures are required.

Machined fixtures: High-precision components from metal or engineered plastics for tight tolerance alignment and rigid support of critical instruments.

3D printed fixtures: Rapid, lightweight, complex geometries and integrated cable routing — perfect for low-to-medium runs, prototypes and confined spaces. Selective materials available for chemical resistance and temperature performance.

Typical applications

Laboratory pressure vessels and test rigs

Gas distribution manifolds and skids

Mass flow controller banks and calibration rigs

Sensor arrays and instrument panels

Custom pilot plants and R&D setups

Why Forge Pressure Equipment

Practical experience with pressure systems and instrumentation ensures fixture designs address not just fit but load paths, safety and maintenance.

End-to-end delivery from design iteration and prototyping through manufacture, finishing and installation.

Flexible production choices minimise cost and lead time while meeting functional requirements.

Next step Tell us the components, environment, quantity and any drawings or photos. We’ll propose the optimum fabrication route, lead times, cost estimate and a prototype option if required.